Corrosion research

The core task of the Antwerp Maritime Academy Corrosion Team (Amacort) is to assess the present and future (corrosion) condition of the munition at the Paardenmarkt dumpsite. Since we are not allowed to bring any shells to the surface and determine their state by observation and measurement, we have to rely on an experimental approach, statistical analysis and modelling.

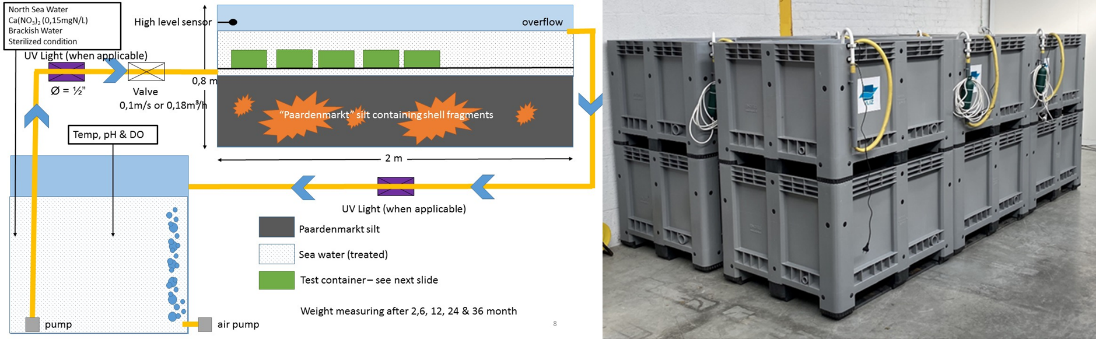

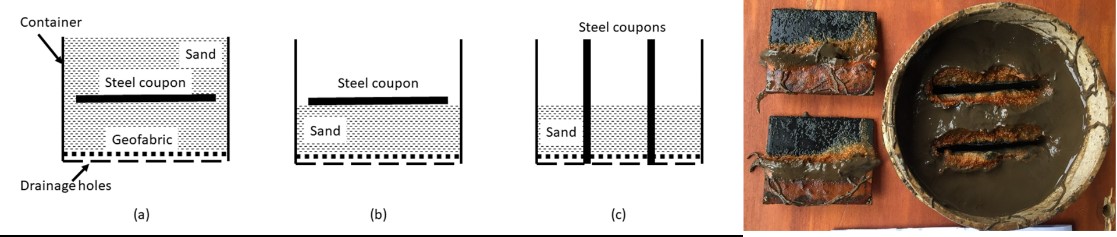

The corrosion rate of such a shell is a complex process due to the diversity in materials the shells are made of, and due to the wide range of environmental conditions they were (and are) exposed to over the last century. This diversity is reflected in our model and in the experimental procedure: in total more than 3000 couponsof 60x60x3mm, made of iron, messing and zamak (a zinc alloy), will be exposed to freshwater, brackish water and seawater, at a custom-built installation at the Marine Station in Ostend (see figures 1 and 2). Other coupons will be buried in silt and sand, and a third set will be exposed to increased concentrations of corrosion stimulating bacteria and corrosive gasses. Apart from the metal coupons mentioned above, fragments of real grenades will be buried in the sand/silt mixture as well, to help us estimate what a real shell could have undergone. The corrosion rate will be calculated by weight loss measurement and this after 2, 6, 12, 24 & 36 months.

We expect to see different forms of corrosion as well. Besides general and pitting corrosion, a lot of attention will go to the galvanic corrosion process at the iron-messing and iron-zamak interface. Moreover, the chemicals inside the shells may even cause them to corrode from the inside. This will be studied in collaboration with the University of Ghent, which has specialized in and approved facilities at its disposal for the study of Yperite (mustard gas) and arsenic compounds. Finally, a separate set-up will be installed at the DOVO site in Poelkapelle, in a safe environment, to work with shell fragments still containing explosive materials.

At this moment the set-up works are in full progress (Figure 3) and we hope to be up and running by the end of 2020.

Website developed and maintained by

Website developed and maintained by